A brake master cylinder is the hydraulic actuator that sends hydraulic (brake) fluid through the lines to each wheel. While all brake masters work the same, they differ in design and bore size. The master cylinder consists of a main body, reservoir (integral or divorced), piston, and seals. They are simple in construction.

How a Brake Master Cylinder Works

Brake fluid test strips are the best way to determine if your fluid must be changed.

The pushrod directly connects the master to the brake pedal. When you press the brake pedal, the rod pushes the piston forward in the master cylinder. This pushes fluid from the reservoir into the brake lines. When you release the pedal, the fluid returns to the reservoir.

Fluid does not compress. When confined in a brake line, any pressure from the brake pedal is directly transferred to the braking components, which is why the pedal gets hard to press at the bottom of its travel.

However, air is compressible. When there is air in the lines, it acts as a cushion for the fluid, so you don't have nearly the same pressure on the braking components doing the work.

There are three main ways for a brake master cylinder to fail: seizing, internal leakage, and external leakage. Any one of these can occur in a master cylinder, regardless of its age. A master cylinder should last the life of the vehicle, but it rarely does. Most of the failures in a master cylinder are due to wear and lack of maintenance.

Brake fluid pulls moisture directly out of the air. Brake systems are not sealed. The fluid in the reservoir is exposed to air. Over time, the fluid picks up water, which causes corrosion in the lines, calipers/wheel cylinders, and the master cylinder. Dirt also gets in. Old and dirty fluid cuts at the metal and seals inside the master cylinder, eventually creating an internal leak.

Signs of a Failing Master Cylinder

You can track down the culprit by pressing the brake pedal and looking for signs of failure.

There are multiple signs of a failing brake system, which can occur in the master cylinder, lines, brake pads, calipers, or wheel cylinders. It takes detective work to find the culprit. Most people notice reduced braking performance. This may be a spongy pedal, pulling to one side, rear brakes locking up, no brakes, the pedal hitting the floor, a very hard pedal, or the pedal not returning to the resting position.

Diagnosing a Bad Master Cylinder

This is a brake bleeder on a brake caliper (disc brakes). A half-turn is usually enough to get good flow.

There are a few quick tests used to determine whether your master cylinder is working properly. Before doing any of these tests, check the fluid level in the master cylinder. Top off to the full line if it’s low.

Press the brake pedal once and hold. The pedal should have increasing resistance as you press down. If not, then you likely have air in the system. Pump the brakes a few times and then hold. Does pressure build? If so, then you have air in the system. Bleed the brakes and retest.

Does the pedal build pressure and then get soft? If so, this shows a leak. Check the entire braking system for leaks. If you don’t see any, have an assistant press the pedal while you hold each flexible brake hose to see if they swell. If the hoses and lines are in good shape, the master cylinder is likely the problem.

Open the master cylinder and leave the cap off. Have an assistant operate the brake pedal. You should see a stream of fluid jump from each chamber as the pedal returns to the top. If not, the master cylinder is likely failing.

Testing the fluid flow requires an assistant. Have the helper press and hold the brake pedal while you open one brake bleeder. Fluid should come out in a strong stream. Tighten the bleeder and have the assistant release the pedal. If no fluid comes out, a line is plugged, or the master is not working. If the fluid sputters, there is air in the line. Bleed the system and retest it.

Replacing a Brake Master Cylinder

An empty reservoir can mean you have a leak or the fluid has just dried up.

Replacing a master cylinder usually takes 30 to 60 minutes. See our

article and video

- opens in new window or tab.

for step-by-step instructions. The hardest part is bleeding the system. Bleeding can be done with two people or by yourself with a pressure/vacuum bleeder.

Can you rebuild a master cylinder?

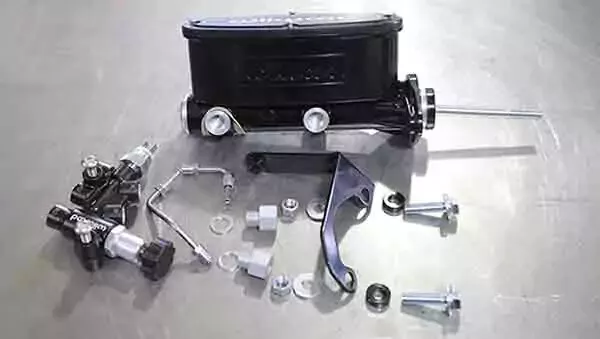

Yes. In fact, it’s the cheapest way to get back on the road quickly. Unless the main body of the master cylinder is severely worn, corroded, or has physical damage, it can be rebuilt with a kit. The main components of a basic kit are a piston, snap ring, plunger cup, spring, and seals. It takes about five minutes to disassemble a master cylinder and replace the parts.

This process can be used on any brake master cylinder that has an internal leak or is stuck. However, a stuck master could have internal damage that is not repairable and needs to be replaced.

What does it cost to replace a brake master cylinder?

Most brake master cylinders cost between $65 to $250, depending on the vehicle. A rebuild kit typically costs $15 to $50.

To find the right brake master cylinder, use the

eBay Parts Finder

- opens in new window or tab.

. Enter your year, make, model, engine, and trim to search for brake master cylinders designed for your vehicle. More information on choosing the right brand is in our

brake master cylinder buyer’s guide

- opens in new window or tab.

.

What tools do you need?

Besides a few hand tools, you need a set of line wrenches. These are like box-end wrenches with a notch cut out to fit over your brake lines. These do not round off the fittings the way open-end wrenches do. A pressure or vacuum bleeder is really handy but not required. Finally, you need brake parts cleaner and fresh brake fluid. Make sure it’s DOT 3 or 4.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.