Unless you drive a car from the 1950s or 4x4 from the 1980s, your vehicle has independent front suspension, and that front suspension uses ball joints. These special articulating ball joints connect the suspension arms to the steering spindle, also called a knuckle. While the design of modern suspension systems has changed, the ball joint has been the same for over 60 years.

Over time, these joints wear out and break. There are typically many warnings that they are failing. If you do not heed these warning signs, you can suffer a catastrophic failure. It could not only seriously damage your vehicle, but also put your life in jeopardy. When a ball joint fails, the suspension is no longer connected. Everything can come apart, and you’ll lose control of the vehicle. As you can imagine, it’s scary at 10 miles per hour. It’s deadly any faster than that.

What a Ball Joint Does

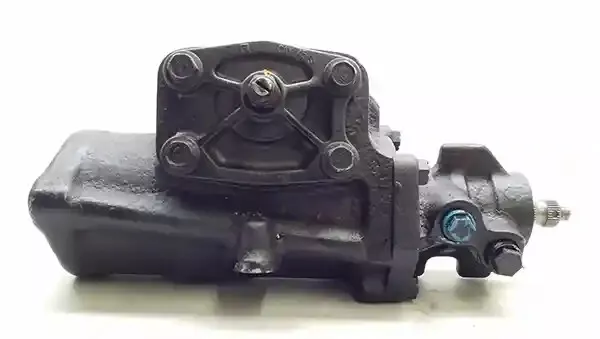

This is a typical ball joint mounted to the spindle from the upper control arm.

A ball joint is just like your hip joint. In a typical modern car, the socket mounts to the control arm, and the ball shaft rotates inside the socket. It’s just like your thigh in the pelvis. The ball shaft—called the taper pin—is installed into a tapered hole on the steering spindle. Most vehicles have two to three ball joints per side. There is usually one upper and one or two lower, depending on the design. These are the basics, and they’re true of all cars.

As the suspension raises and lowers during normal operation, the ball joints allow the steering knuckle to stay perpendicular to the road instead of angling in/out as the arms move. This keeps your tires flat. Without ball joints, you wouldn’t have any stability.

Signs Your Ball Joints Are Going Bad

The taper pin slides into the knuckle/spindle taper and usually has a cotter pin with a castle nut holding it in place.

The entire weight of the vehicle is on the ball joints. These have to endure the bumps and potholes of driving, as well as the torsional stress of turning. Over time, the ball and socket wear on each other, making them sloppy. This is when you start to notice signs. Popping and clicking when turning the wheels is the first sign. This is most noticeable at low speeds. As the wear gets worse, the noises get louder and more frequent.

Vibration when braking, turning, and on uneven/bumpy roads is another sign of a failing ball joint. For instance, the steering wheel may have more play than normal. Anything more than 1/8-turn of free movement is a problem. The vehicle may wander without steering input, and you should look for adverse wear on the inner treads of your tires.

While catastrophic ball joint failure is rare, it does happen. This occurs when the ball pops out of the socket. In most cases, you get what’s called the “death wobble.” The front suspension starts moving violently in an uncontrolled manner. After that, the front suspension collapses, the front end crashes to the ground, and the vehicle grinds to a halt. The faster you are going when it happens, the worse it is. This can total your vehicle. The chassis, body, and drivetrain all can be severely damaged.

Check Your Ball Joints by Hand

Many older vehicles have riveted-in upper joints. This vehicle is 25 years old with 190,000 miles. These are the original ball joints. You have to grind the rivets off when equipped.

You can perform a quick check by grabbing the tire at the top of the wheel and then pushing and pulling hard on the tire/wheel. The vehicle should rock and sway, but it shouldn’t make a clicking sound. The wheel should not move independently of the body. If the wheel feels loose at all or clicks, you have an issue.

Here’s the more thorough check. Raise the front end of the vehicle so the suspect wheel is off the ground. Always support the vehicle with a jack stand, not just a jack. Perform the same action as stated above: push and pull on the wheel top and bottom. It should be firm and not wiggle. If it wiggles around, the ball joints are worn and need to be replaced. Other bushings/joints can be worn as well.

How long should ball joints last?

Most ball joints last between 70,000 and 150,000 miles, depending on make and model. Heavy-duty vehicles—as well as vehicles driven on rough terrain such as dirt, gravel, and potholed roads—require more frequent ball joint changes.

Yes, You Can Service Your Ball Joints

Don’t forget to grease your suspension joints. It helps them last much longer.

Back in the day, this was called a lube job. That term isn’t used much anymore as it’s such an ignored service. Most vehicles have greaseable ball joints, which should be greased with every oil change. Even staunch gearheads ignore this. If you want the most life out of your vehicle, regular lube jobs on all of the greaseable parts of your suspension is how you get it.

Replacing a bad U-joint isn’t impossible, but it’s not the simplest car repair. See our

article and video

- opens in new window or tab.

for complete step-by-step instructions.

With the right tools, you can easily do this job yourself in your driveway in a couple of hours. If you have a modern vehicle with McPherson struts, it’s an easier fix. These vehicles don’t require removing the coil springs to get out the ball joint. Older vehicles with coil spring suspension are a little more difficult to work on, because you need to compress the coil spring to do the job safely. Many newer vehicles do not have replaceable ball joints. Instead, you replace the entire control arm. These are even easier to do because you don’t have to press out the old joint.

We recommended that you replace all of the ball joints when servicing one. By the time one has begun to fail, the others are right behind it. Worse, one new joint will put even more stress on the old ones, hastening their failure. It’s faster to do it all at once.

While you are at it, refresh the entire suspension with new tie rod ends, sway bar bushings/links, and maybe even the shocks or struts. This is not required, but it’s a good idea as you already have everything apart.

There is one final thing to know. After you replace the ball joint, the vehicle must be aligned at a shop. This is non-negotiable. If you don’t, your tires won’t wear properly, and the steering can’t track the way it should. Your vehicle will pull to one side or the other. An unaligned car eats tires, too. It’s just not economical or safe.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.