Power steering used to be a luxury feature, but these days, nearly every vehicle on the road has it. If you don’t have power steering, every turn of the steering wheel requires muscle, especially at low speeds.

Has your steering wheel suddenly become much heavier than it used to be? That’s a sign that your power steering pump has failed and needs to be replaced.

How long does it take to change a power steering pump?

Power steering pump replacement is a beginner do-it-yourself mechanic job that usually takes one or two hours.

The replacement process requires a special power steering pump pulley removal/installer tool. Some pumps come with new pulleys installed, but this is not common. The original pulley is usually reused.

Our demo vehicle uses a V-belt accessory drive. We selected this vehicle to show the process with the more complicated V-belts. If your vehicle has a serpentine belt, the process is a little easier but follows the same basic steps.

Tips and tricks

for power steering pump replacement

-

We recommend installing new belts and hoses when replacing the pump. If your vehicle has an inline fluid filter, replace that as well.

-

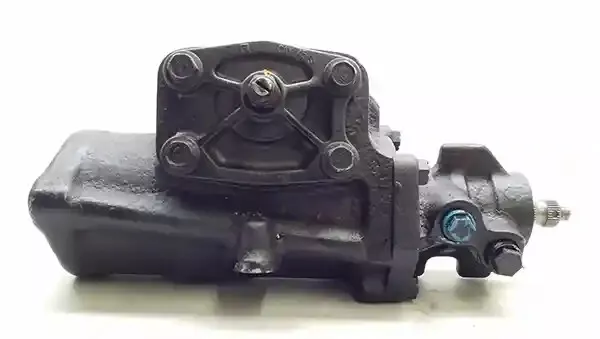

Power steering pumps have not changed much over the years, but they look different from one another. Some vehicles use integral reservoirs, while others have remote reservoirs for the power steering fluid.

-

The pump is about four inches in diameter. The pump can be located anywhere on the engine’s accessory drive, but it is most commonly placed on the driver’s side.

-

Less than 10 percent of new cars have electrically powered rack-and-pinion steering. This article focuses on mechanical/hydraulic steering systems.

Pop the hood to locate the power steering pump. If you can’t find it, look for the steering column, follow that to the gearbox, and trace the lines to the pump.

There are typically two lines on the pump. If you have an internal reservoir, the return line is usually secured to the pump’s return fitting with a basic hose clamp. Meanwhile, the pressure line has a larger high-pressure fitting that requires a line wrench to loosen.

If you have an external reservoir, the pump has a large low-pressure feed line from the reservoir secured with a hose clamp and a single high-pressure fitting. The return line goes to the reservoir.

Some vehicles use thread-on fittings for both lines, but the return side is usually the smaller one.

Loosen the pump bolts so you can remove the belt. Our demo vehicle uses a V-belt drive. The V-belt tension might be adjusted at the alternator.

If you have a serpentine system, use a breaker bar or socket (if required) to release the tension from the belt. Pull it off the pump pulley.

Inspect the drive belt for wear or damage. This V-belt has slight fraying on the edges and weather cracks along the sides and grooves, so it needs to be replaced.

Disconnect the hoses from the pump and direct the fluid to a drain pan or cup. There is not much fluid in the pump—a couple of quarts at most.

Loosen the hose clamp and remove the return line. Use a line wrench to remove the pressure line.

Flush the steering gearbox of old fluid by turning the steering wheel lock-to-lock until no more fluid comes out.

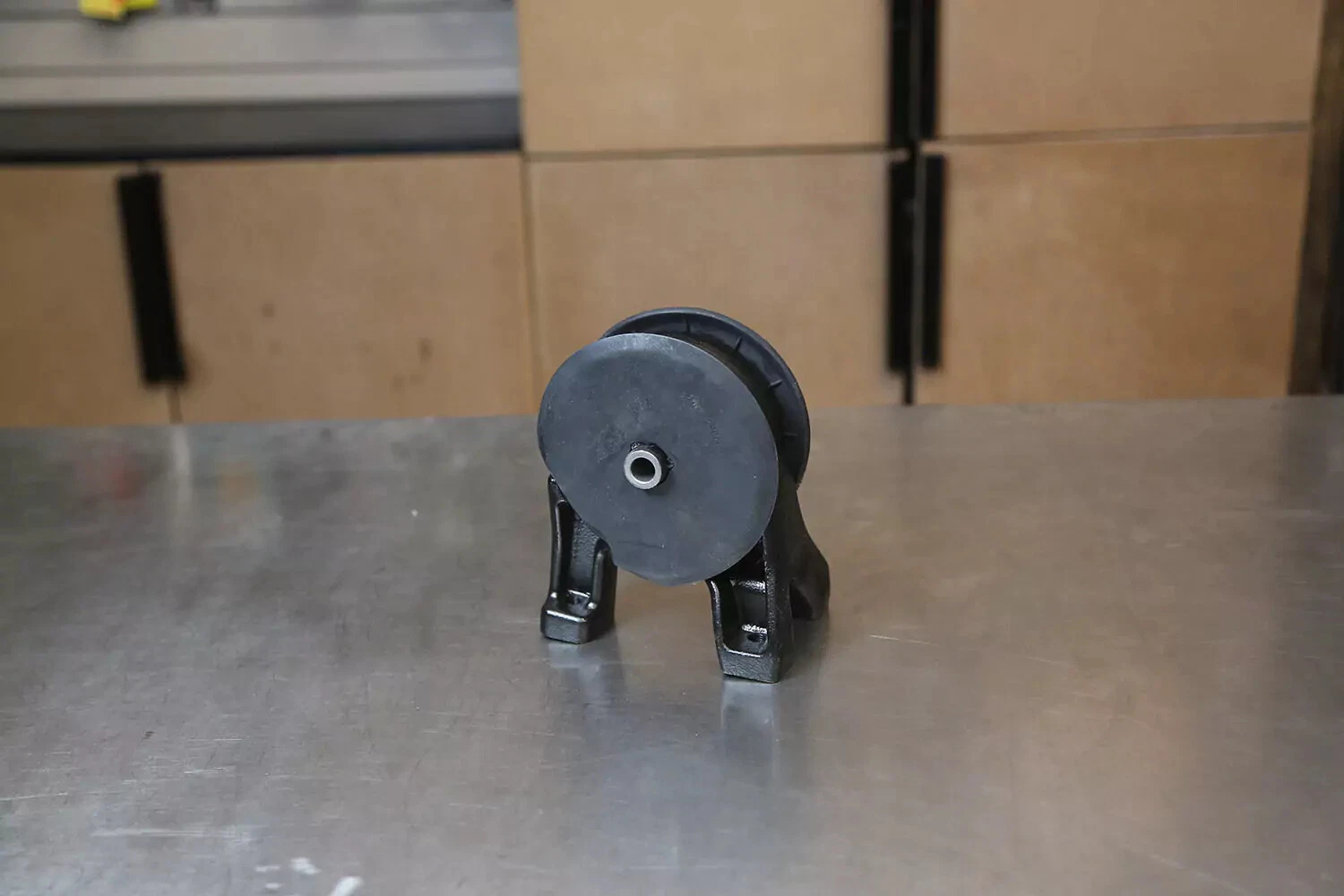

Depending on your vehicle, you may need to remove the pulley before you can take out the pump. That was the case with our demo vehicle.

Most power steering pulleys have a notch on the front. Use the clamshell puller tool for this style.

If your pulley has two (or three) threaded holes around the center shaft, you need a bolt-on style puller.

Use the correct tool to pull the pulley off the pump. Our pump is the clamshell type, which requires two wrenches—one to hold the puller steady and one to turn the jackscrew to push the pulley off the shaft.

Remove the bolts and pull the pump from the brackets. If your engine compartment is crowded, this step might require adept maneuvering to remove the pump.

With the old pump removed, position the new pump into the vehicle.

Install the bolts that hold the pump to the bracket. If you have a serpentine drive, tighten these bolts now.

For V-belts, tighten the bolts enough so the pump can rotate on the sliding bracket without wiggling.

Using the installer side of the pulley tool, install the power steering pump pulley to the pump. This is usually done by threading the tool into the pump shaft. Thread it in all the way and back it out by a single turn. Then, use two wrenches to draw the pulley onto the shaft. Stop when the tool bottoms out and gets tight.

The pulley should sit flush with the pump shaft, as shown.

The pump shaft should not stick out or sit inside the pulley. It needs to be flush for proper alignment with the rest of the pulleys.

Install the drive belt and set the tension. For serpentine belts, release the tensioner onto the belt.

For V-belts, use a pry bar to carefully rotate the pump away from the center of the engine until the belt is tight. Then, tighten the bolts on the pump brackets.

When properly tightened, V-belts should have about ½-inch of vertical slack. The old mechanic’s saying is “the rule of thumb,” meaning the belt should be able to flex the thickness of your thumb when correctly tightened.

The belt should be tight but have flex. If it’s too tight, there will be too much strain on the bearings.

Install the hoses to the pump in their original positions. Do not overtighten the fittings, as you could damage the pump or fitting.

Fill the reservoir with fresh power steering fluid that matches the required specifications for your vehicle. Power steering fluid is not universal. Some vehicles, such as most German and many Japanese makes, require specific types of power steering fluid.

Verify the type you need via your vehicle’s owner’s manual.

Fill the power steering pump with fresh power steering fluid. Some vehicles use a dedicated fluid, while others specify automatic transmission fluid (ATF). See the recommended fluid on the reservoir cap or owner’s manual.

Lift the front wheels off the ground so you can freely turn the steering wheel. Then, start the engine and slowly turn the steering wheel all the way from one side to the other—lock to lock—about 20 times. This will bleed the air from the system.

The fluid level should not drop below the halfway mark. If it does, add more fluid. Running out of fluid can damage the pump.

If the system groans or whines or the fluid is foamy or bubbly after 20 turns, turn it another 20 times. If it still makes noise or is foamy, there might be a leak in the return line. Either a hose is damaged, or the fitting isn’t properly tightened.

After you bleed the gearbox, top off the reservoir to the full mark. Lower the vehicle off the jackstands. The vehicle is ready to drive.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.