Today, you’re only likely to find an idler arm in a parallelogram steering linkage on heavy-duty trucks and off-road 4x4s. The parallelogram steering linkage consists of an idler arm, pitman arm, center link, and tie rod links. This once-common setup fell out of favor in an industry shift toward rack and pinion steering. The last cars with recirculating ball steering gear parallelogram linkages rolled off the assembly line in the 1990s.

What Is an Idler Arm?

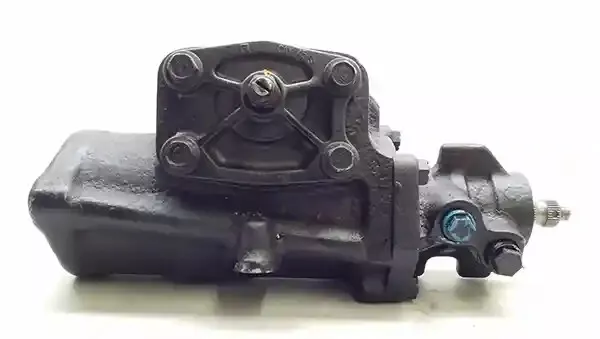

A replacement idler arm for 1990-2000 General Motors pickup trucks.

Again, an idler arm isn’t something you’ll find on a modern car or even on standard-duty trucks. Still, it’s part of a robust design that is still in production. Let’s go over how the whole system functions.

The parallelogram steering linkage gets its name from the way it works.

-

The steering wheel and column connect to the input shaft of a frame-mounted recirculating ball steering gear, also known as a steering box.

-

The pitman arm connects the output shaft of the steering box to the center link on the driver's side.

-

The idler arm extends from the frame to the center link on the passenger side.

-

Tie rod links connect the ends of the center link to the steering knuckles on the wheel hubs.

When the steering wheel is straight ahead, the idler arm, center link, and pitman arm form a square. When the driver turns the steering wheel, the square turns into a parallelogram. The pitman arm transfers driver input to the center link. The idler arm follows the pitman in parallel, allowing the center link to move left and right while preventing it from moving up and down. The tie rod links move the steering knuckles, wheels, and tires in parallel and keep things on track. It’s not the most refined steering system, but it works!

Today's cars and standard-duty two-wheel drive pickup trucks use a rack and pinion steering. The horizontal rack mounts directly to the frame or subframe and eliminates the idler arm, center link, and pitman arm by design. Rack and pinion steering is not tough enough for heavy-duty trucks and 4x4s, however. They still use recirculating ball steering gearboxes and parallelogram steering linkages. They can handle far heavier axle loads and punishment than rack and pinion systems.

How do you tell if you have a bad idler arm?

A worn-out or faulty idler arm can cause problems that range from annoying to dangerous. Constant minor steering corrections while driving down the highway can signal that an idler arm is beginning to go bad. Vibration, clunking or thumping noise from the front end, loose or vague steering, tire squeal on turns, and feathered tire wear are all signs that the idler arm is on its way out. Total malfunction or separation failure can result in a sudden and catastrophic loss of steering control. Not ideal.

So what is physically happening as an idler arm goes bad? Vertical movement of the center link increases as the idler arm wears out. When the center link moves up and down, the tie rod linkages push and pull the ends of the steering knuckles off parallel. That knocks the wheel’s toe alignment out of whack as you drive. To visualize what's going on, stand back on your heels and move the front of your feet toward and away from each other in random directions. Your front wheels and tires do this when the idler arm goes bad. Toe in. Toe out.

How Long Idler Arms Should Last

Greasing a replacement idler arm is standard practice.

The idler arm and parallelogram steering linkage parts can last as long as your vehicle, but that’s under normal driving conditions. Heavy or severe duty use on or off the road can shorten service life. Regular inspection and maintenance can extend it.

Tapered ball joints need grease to survive regular and punishing road conditions alike, but automakers don't always install grease fittings at the factory. Road grime and crud due to rubber grease boot or seal failure can cause premature failure. If you find yourself with a worn-out idler arm within even tens of thousands of miles, start looking for something that may be wrong in your steering system.

How to Check for Idler Arm Wear

To check for movement in the steering components, use a floor jack and jackstands to take the weight off the wheel.

Symptoms of a bad idler arm are easy to feel. A worn idler arm is easy to see and hear with a helper and a light. One method is to park the vehicle with the engine off and the parking brake on. Get a good view of the idler arm with the light. Have your helper turn the steering wheel. Look and listen for movement and play at the idler arm and center link. Torn or missing grease boots are a sign of impending failure.

If you have a jack and jack stands, lift and secure the front of the vehicle so the tires are off the ground. Have your helper grab and move each front wheel and tire first from the sides and then from the top and bottom. Watch and listen for movement at the idler arm, pitman arm, tie rod, and ball joint linkages. Get a good hand grip on suspected bad parts and check for excessive movement. Anything more than a little is too much.

Replacing an Idler Arm

Idler arm replacement takes a bit of muscle and basic hand tools.

The difficulty of replacing an idler arm and bracket depends on the vehicle. Take a long view of the steering and suspension during inspection. It’ll help you in the whole process. Idler arm bushings, swivels, and tapered ball joints can wear out faster than other steering components, but removing and replacing one worn part won't solve your problem if there's a shimmy in the rest. A little slop can add up to a lot across several linkages.

See our complete detailed step-by-step guide and video for

how to replace an idler arm

- opens in new window or tab.

.

Replacing an idler arm is cost-effective

An idler arm is a relatively inexpensive player among replacement parts. It’s certainly far less expensive than the damage it can cause from failure. At a minimum, expect the cost of a new set of tires from uneven wear.

Our

DIY guide

- opens in new window or tab.

gives you a practical look at the time, tools, supplies, and skills required to finish the job within your budget. Check out our idler arm buying guide for an in-depth cost rundown of the different idler arm types, grades, and applications.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.