Manual transmissions are no longer popular, but they are the most efficient transmission design. They are simple and durable. Maintaining them requires changing the transmission fluid every 30,000 to 60,000 miles. If you regularly drive through water, mud, or dirt roads, change the transmission fluid more often.

Check your owner’s manual for the recommended fluid for your transmission.

Replacing the transmission fluid is a simple process: drain, fill, and drive. Most manual transmissions hold about two quarts of fluid. We recommend having at least three quarts on hand.

You will need a transfer pump to get the fluid into the transmission. The fill port is usually in a tight space between the transmission and the tunnel of the floor. Simple hand-pump tools cost around $20.

This project requires working under a lifted vehicle. Be sure you are in a safe area and that the vehicle is safely lifted and supported.

Tips and Tricks

-

A three- or four-speed transmission from the 1980s (or older) requires gear oil, which is thick and smells bad. It’s the same stuff used in the differential (axle housing).

-

Modern transmissions use either manual transmission fluid (MTF) or automatic transmission fluid (ATF). Modern manuals have tighter tolerances, synchronizers, and bearings that are not compatible with gear oils.

This project requires working safely under the vehicle. You will need a floor jack, and jack stands, ramps, or wheel cribs to support the vehicle.

Locate the factory jacking points just behind the front wheels or just in front of the rear wheels. The jacking point is a metal section with two V notches about two inches apart. Check your owner’s manual to confirm the lift location.

Never use jack stands on dirt, gravel, or asphalt. If you do not have access to a concrete work surface, use wheel cribs, solid-base ramps, or wide-base wood supports to support the vehicle. Never use cinder blocks or bricks as supports.

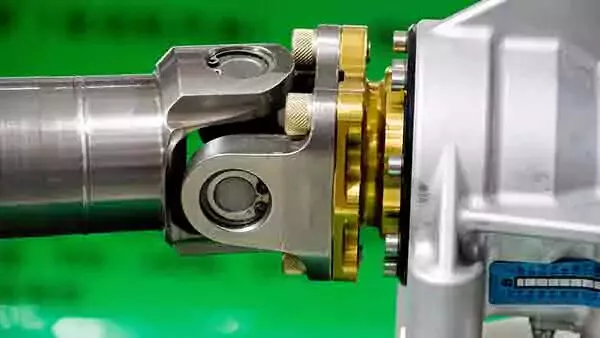

The drain plug is typically at the rear of the transmission's main body (in the lowest section).

Most plugs use a square drive, such as a ratchet connection. But some use a socket, Allen, or Torx bit.

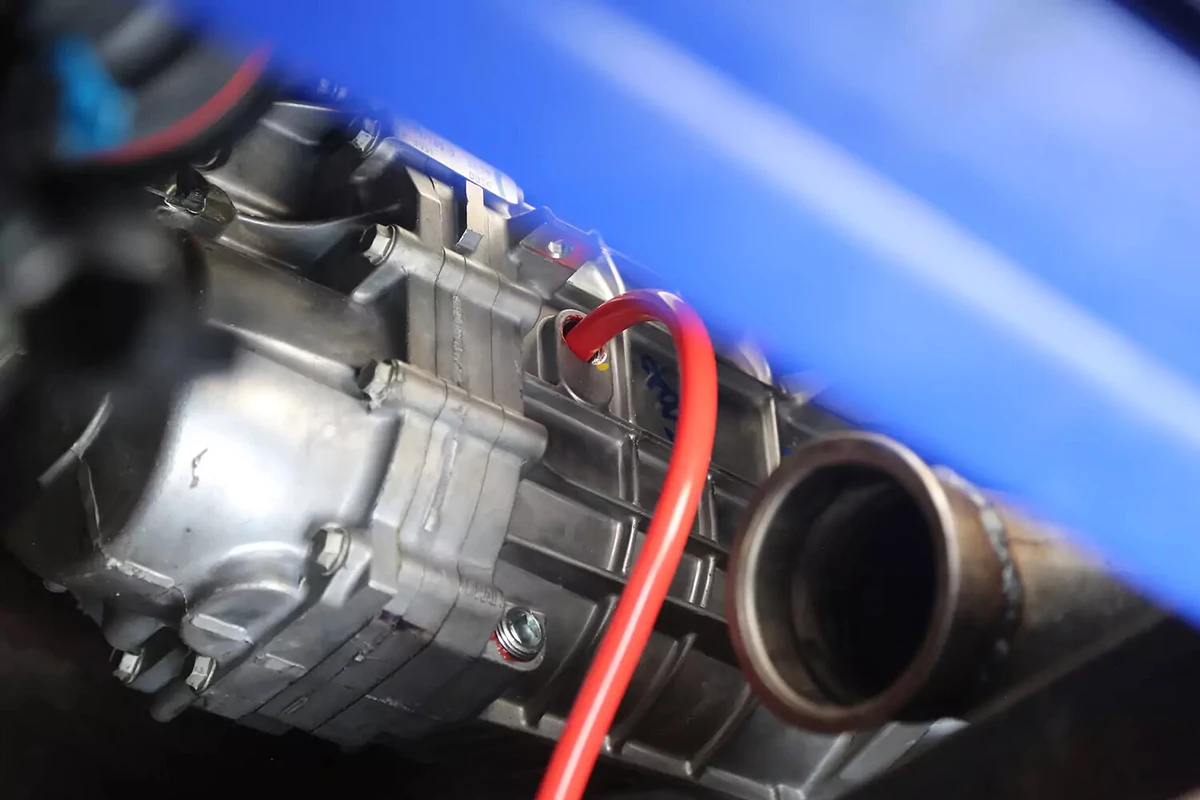

We removed the exhaust in our demo vehicle to photograph the process more easily. That’s not required to change the transmission fluid.

Loosen the plug, but don’t pull it out yet.

Move the drain pan under the drain plug. Position it to capture the flow, which will be heavy at first and then slow to a trickle.

Remove the plug. Allow the fluid to fully drain until the stream is single drops.

If your transmission uses gear oil, this process could take 10 minutes or longer, especially if the engine is cold.

While the fluid is draining, clean the plug. If it’s a magnetic plug, remove small metal fragments.

Reinstall the drain plug after the fluid slows to a drip. Get as much of the old fluid out as possible.

If the drain plug has a washer, replace it.

Do not overtighten the plug, which can strip the threads. Most drain plugs require 20 to 40 pound-feet of torque. Verify the torque spec in your repair manual.

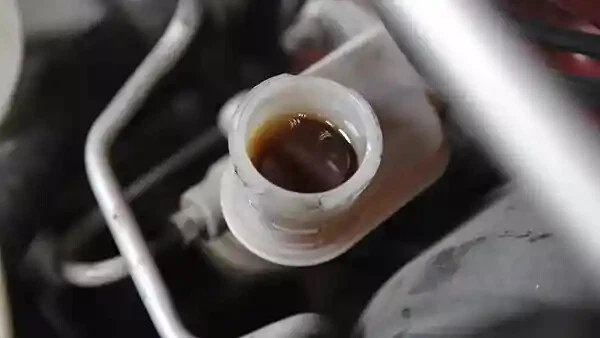

Locate and remove the fill plug. It is usually just above the transmission’s horizontal midline. The fill plug typically uses the same socket as the drain plug.

If there’s sufficient room, insert the spout of the gear lube bottle into the transmission filler neck. However, most vehicles require a transfer pump. Set the pump up with one hose as the input and another one as the output.

The hoses are different lengths. You can work under or outside the car, depending on the hose you select for the output.

Slide the fill hose into the fill port, pushing the hose past the threads. The fluid can drip from the threads if the hose is not all the way in. This could give a false impression that the transmission is full.

Insert the input (suction line) into a fresh bottle of the correct fluid. Ensure the hose is at the bottom of the bottle. An assistant is helpful to monitor the bottle as you pump.

In cold conditions, it could help to warm the fluid to make it less viscous.

Pump the fluid into the transmission until it begins to drip out of the fill port. This is why you need to make sure the hose is pushed in beyond the threads.

Most manual transmissions do not have filters or dipsticks. You’ll know it is full when the fluid is level with the bottom of the fill port threads.

Reinstall the fill plug with a new crush washer (if so equipped). Torque the fill plug to the same spec as the drain plug.

Clean up any spillage and lower the vehicle. Note the current mileage so you know when to change it again.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.