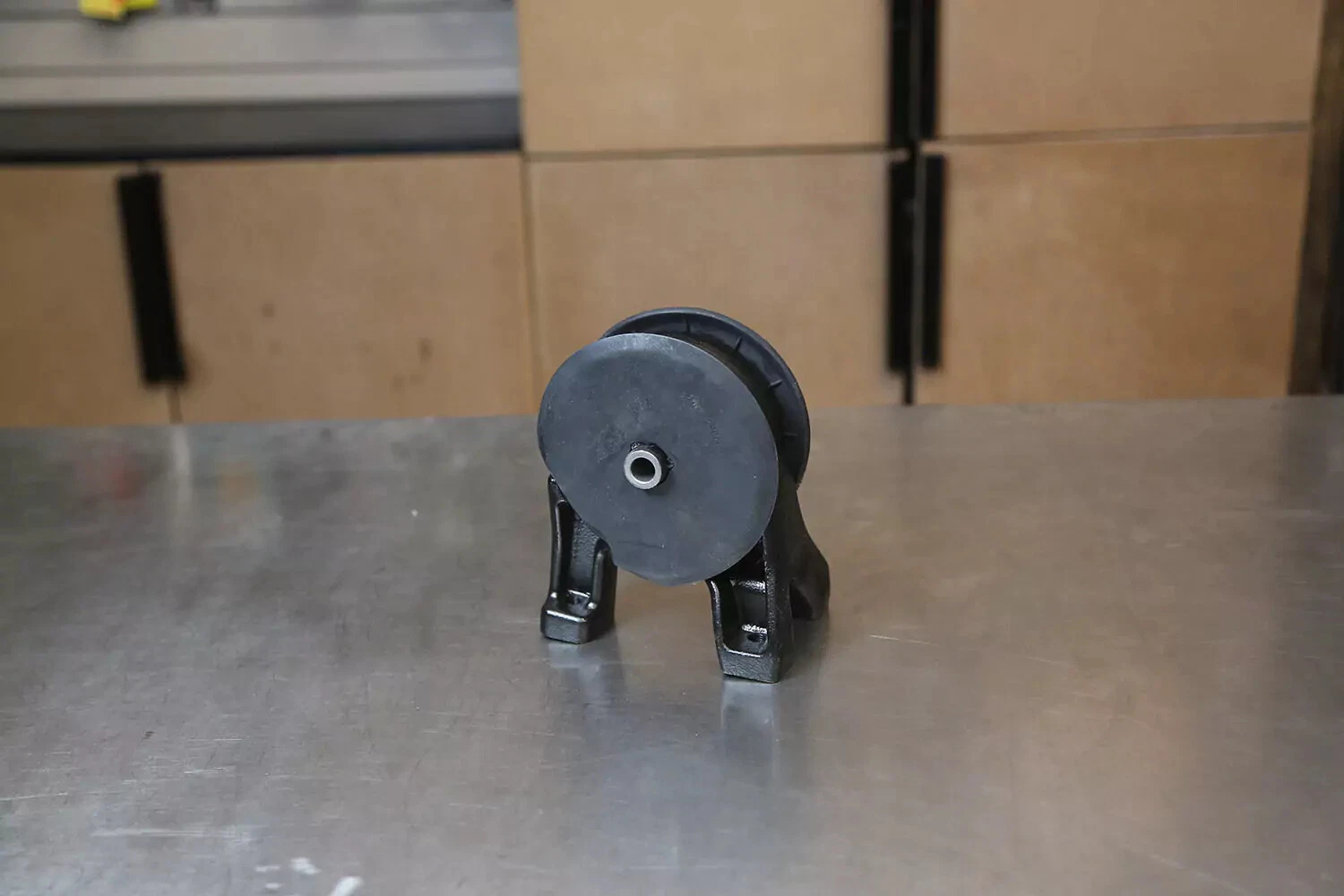

The U-joint allows for play while the vehicle is in motion. But it should be minimal.

The U-joint is responsible for allowing the driveshaft to move freely along with your vehicle’s suspension. If your U-joint wears out or develops too much play, you could be in for a bumpy ride, or your car might not move at all.

There are two big considerations when buying a U-joint:

OEM vs. heavy duty

: For most stock vehicles, an original equipment manufacturer (OEM) U-joint is durable and strong enough. They can last 100,000 miles. If you have a modified vehicle that you race on the track or take off-roading—or if you have a lift kit—there’s extra strain on your drivetrain. Consider upgrading to heavy-duty aftermarket U-joints. Dana and Spicer are two well-respected OE suppliers that sell aftermarket parts. Or look for ACDelco and other OEM suppliers.

Greaseable vs. non-greaseable

: Greaseable U-joints have a fitting that allows you to re-grease your U-joints if they regularly get waterlogged or dirty. Non-greaseable U-joints don’t have this level of serviceability, but they are stronger because they don’t have the internal grease channels that you find in greaseable U-joints. Greaseable U-joints require maintenance. Non-greaseable U-joints run until they fail.

Greaseable U-joints should be serviced. Every time you do an oil change or any time you find yourself wading through water or mud, we recommend attaching a grease gun to your U-joints and filling them until fresh grease runs out of their seals.

If your U-joint is exhibiting play and new grease doesn’t fix the problem, the U-joint needs to be replaced, not rebuilt. Non-greaseable U-joints are not meant to be rebuilt or regreased.

See our detailed step-by-step

guide and video about replacing a U-joint

- opens in new window or tab.

. Also, learn more about the

types of U-joints and when they go bad

- opens in new window or tab.

.

How Much Does It Cost for a New U-Joint?

MOOG is always a solid choice.

A standard U-joint from a reputable OE or OEM costs between $20 and $50. Heavy-duty versions can get up to the $75 to $100 range. Look for reputable names like ACDelco, Dana, and Spicer, which provide high-quality, long-lasting parts. With U-joints, you get what you pay for.

Replace your U-joints once you begin to notice symptoms of them going bad. Driving on a bad U-joint creates play in the whole driveline and can accelerate wear on these other parts:

Differential seals:

The vibrations produced by a bad U-joint can damage the seal at the front of the differential. Check around the front of the differential for leaks. It may need to be replaced.

Driveshaft:

Replacing your U-joints requires removing your driveshaft. Vibration from bad U-joints can damage the driveshaft and throw it out of balance. Check

our guide on balancing driveshafts

- opens in new window or tab.

to see if it needs to be replaced. This is the perfect time.

Transmission seals

: Just like the differential seals, bad U-joints can damage the seal at the back of your transmission. Check for leaks when you inspect the U-joints.

Yokes:

When you are replacing your U-joints, you may notice burrs or other damage on the yoke where the U-joint connects. These should be filed down and cleaned with a scour pad. The grooves that accept the retaining clips for the U-joints must also be cleaned out. You can get in there with a flathead screwdriver.

Tools and Accessories for U-Joint Replacement

Replacing U-joints is easier with a click-type torque wrench.

You can replace a U-joint with common tools. A socket set, a breaker bar, a torque wrench, and a hammer should get the job done. However, three other tools can make the job easier.

Torque wrench:

You need to torque down the bolts holding in your driveshaft. This is made easier with a torque wrench. Get a click-type torque wrench because you will face tight confines that make a beam-type torque wrench challenging.

U-joint press tool:

You can hammer out a U-joint using a hammer and a socket that’s the same diameter as the bearing cap on the U-joint. But a U-joint press does the same thing with less effort and more precision.

Vice:

A bench vice makes it easy to firmly hold the driveshaft by the ends or yoke. The vice secures a position to press out the old U-joint and press in the new unit.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.