Every gas-powered engine uses spark plugs to ignite the air/fuel mixture in the combustion chamber. There are two ways the plugs are connected to the distributor or ignition coil: plug wires or coil-on-plug ignition coils.

Modern vehicles increasingly use coil-on-plug designs, which do away with spark plug wires entirely. This article is focused on engines with ignition (or plug) wires.

Whether your engine uses a distributor, coil banks, or individual coils, the plug wire itself is the same. The only difference is length and sometimes the terminal connection to the cap or coil.

What Are Spark Plug Wires?

The red outer jacket covers the inner support jacket, which protects the black suppression layer covering the core.

The ignition wire and plug wire are the same thing. It connects the spark plug to the ignition system. Most modern engines use coil-on-plug technology, but many cars on the road still use plug wires.

Plug wires are made of an outer jacket, suppression layer, insulation layer, and a core wire that carries the electrical current to the plug.

Ignition Wire Types

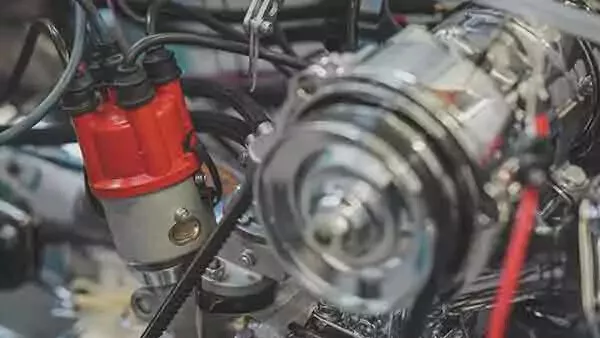

This is a distributor cap with perimeter plug wires. It is a good idea to trace each wire and label it before changing the wires.

There are many different types of ignition wires based on the needs of the engine.

Most plug wires used today are distributed resistance or suppression core wires. These use a spiral-wrapped core made of fiberglass and carbon. This generates a protective radio frequency (RF) suppression field. The core may also be made from stainless steel, copper-nickel alloy, or Kevlar fiber.

Race cars may use copper core wires, which don’t have radio frequency (RF) suppression. This means they make noises through your radio and interfere with the sensitive electronics in modern vehicles. These should never be used on a street car.

There are several layers to a spark plug wire. A stranded alloy wire covers the core, which is covered with a silicone overlay, and finally, an outer layer typically made of rubber or silicone. High-end performance plug wires are usually made with silicone, whereas OEM and replacement wires are usually made with EPDM rubber. Some high-performance ignition wires include a braided sleeve between the two layers of silicone for additional strength and support.

The end terminals of a plug wire are stainless steel crimped fittings. These are covered with a boot, which is usually made of silicone. Specialty plug wires sometimes use ceramic boots for the spark plug side for high-performance applications. The ceramic boot eliminates the chances of a boot melting on hot headers.

If you have an older vehicle that uses a distributor, there is also an extra wire—one more than the number of spark plugs in the engine. This is the coil wire. It runs from the coil to the distributor. Coil wires are the exact same as plug wires, except that the coil wire in a distributor-based ignition system connects the distributor cap to the single ignition coil.

How Long Do Ignition Wires Last?

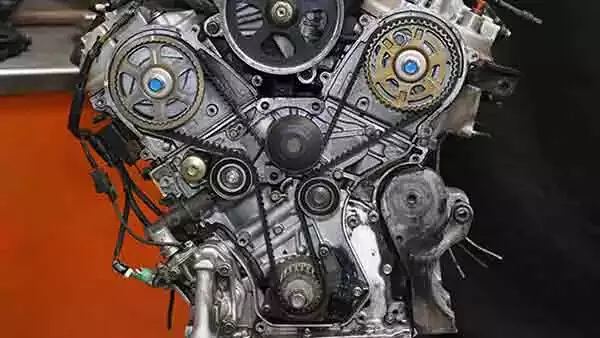

This is a six-cylinder distributor cap and rotor. The individual spark plug wires attach to the six fittings on the outer edge of the distributor cap.

In most vehicles, a set of plug wires is good for 60,000 to 70,000 miles. That’s about the same as spark plugs. We recommend replacing the plugs, plug wires, and other ignition consumables at the same time. This is what is commonly referred to as a tune-up.

If your engine has a distributor, you should also change the distributor cap and rotor. Most engines built after the year 2000 are distributorless. If you have coil banks or individual coils, replace only the plugs and wires. The ignition coils on most vehicles last well over 100,000 miles, so it’s not necessary to change these unless you have an issue. If there’s a problem with your spark, change the plugs and wires and cap and rotor first. If the issue persists, change all the coils together.

Should you replace one bad ignition wire at a time?

It’s possible. But if one is failing, the others likely have similar wear. So the smart move is to complete a full tune-up. The exception is mechanical damage, such as a burn or cut. In that case, it’s OK to replace the single damaged wire.

Symptoms of a Bad Plug Wire

Always use dielectric grease on spark plug wires. It keeps the boots from bonding to the plug and promotes energy transfer while reducing corrosion.

When spark plug wires fail, you can experience misfires, stalling, hesitation, detonation (knock or ping), backfire, hard starts, and reduced performance. These symptoms may start intermittent and become constant. Your vehicle will likely trigger check engine light (CEL) codes referring to misfires and ignition issues.

Physical damage is very common for ignition wires. That shows up mainly as abrasion from rubbing or being pinched or getting burned on hot exhaust. How the wires are routed can also introduce failure symptoms, even though the wires are still good. Plug wires should never be bundled together where they touch. There should always be a minimum 1/8-inch air gap between the plug wires. Otherwise, the spark may jump from wire to wire. This is more common with cracked or damaged wires, but new wires can also experience crossfire.

How do you test ignition wires?

Use a digital multimeter to test an ignition wire. Turn on the meter, set it to measure ohms (the horseshoe sign or the Greek letter omega), and designate the appropriate range. Most spark plug wires have about 5,000 to 8,000 ohms of resistance per foot. You need the specs for the engine to confirm if the wires are still good. These can be found in your vehicle’s repair manual or an online owner’s forum. If the resistance is higher or lower than the range specified, it should be replaced.

Ignition Wires Are a Low-Cost Repair

For a custom-fit wire, special crimpers crimp the terminal to the wire using a bench vice. You can also get handheld crimpers for this purpose.

Most plug wire sets are pre-made to fit specific engines. A set of new ignition wires usually costs between $40 and $100. For daily drivers, the typical plug wire set is sufficient. A high-performance set, which runs as high as $250, offers only small gains in efficiency for stock engines.

Replacing ignition wires is easy. Replace one wire at a time, working around the distributor cap (or coil bank) so that you do not get the firing order out of sync. The plugs must be reinstalled in a specific order. Otherwise, the spark plugs fire at the wrong time, and the engine might not run. This is not a concern for modern coil engines, where the engine control module triggers each coil.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.