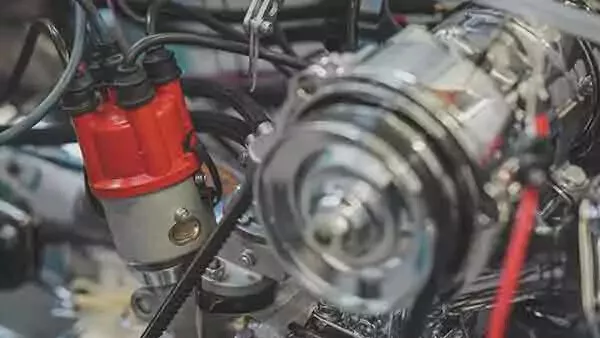

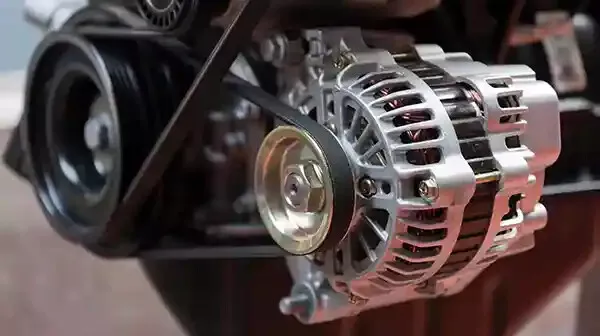

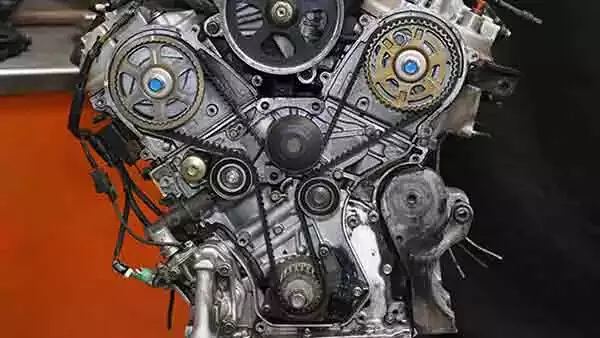

Ignition coils transform your car battery's low-voltage output into the high-voltage energy your spark plugs need for internal combustion. Automotive ignition systems have dramatically changed over the decades. Until the mid-1990s, most cars used a distributor to route spark energy from a single coil to each individual spark plug. Most modern engines built in the last 20 years or so use coil-on-plug or remote-mount ignition coils with one coil per cylinder or sometimes one coil per pair of cylinders.

Whether you have one, two, or eight coils, the process for changing ignition coils is relatively the same.

What Are the Signs of a Bad Ignition Coil?

Each coil in your vehicle fires thousands of times every minute. Although ignition coils are robust, they eventually die and must be replaced. Common symptoms of a failing coil are hard starts, no starts, misfiring, and poor performance.

How Long Does It Take to Replace an Ignition Coil?

You can usually replace an ignition coil in less than 10 minutes. But there are exceptions. For example, if your vehicle has a high-energy ignition (HEI) in-cap coil, the replacement could take 15 minutes longer.

Tips and Tricks for DIY Ignition Coil Replacement

-

In most cases, coils that are original to the vehicle are built to higher standards than aftermarket coils. However, aftermarket high-performance coils deliver more voltage with faster recovery times than stock coils. Your application will determine what is best for your vehicle. If the engine is stock, an original manufacturer coil is best. If you made performance modifications, you might be able to use a high-performance coil.

-

Coil-on-plug ignition systems—where the coil pack is integrated with the spark plug wire—are outliers. The project described below relates to a single coil for every cylinder.

-

On some distributors—such as GM HEI distributors made from the mid-1970s to the late 1990s—the coil is inside the distributor cap. Ignition coils in these engines are more difficult to replace because you must remove the distributor cap to access the coil.

The first step for many auto repair jobs is disconnecting the vehicle’s battery. It’s a simple task. Remove the ground clamp from the battery’s negative post. Plus (+) and minus (-) signs are usually molded into the plastic battery case near the post.

Removing the negative terminal first ensures the vehicle is no longer connected to a live battery. This prevents sparks, electrical shorts, or components (such as fans) from unnecessarily coming on.

Pull the terminal off the battery for a close inspection. If there is corrosion, loose wires, or physical damage, consider replacing the battery terminal or cable.

Move the terminal away from the battery into a position where it can’t accidentally touch the battery post.

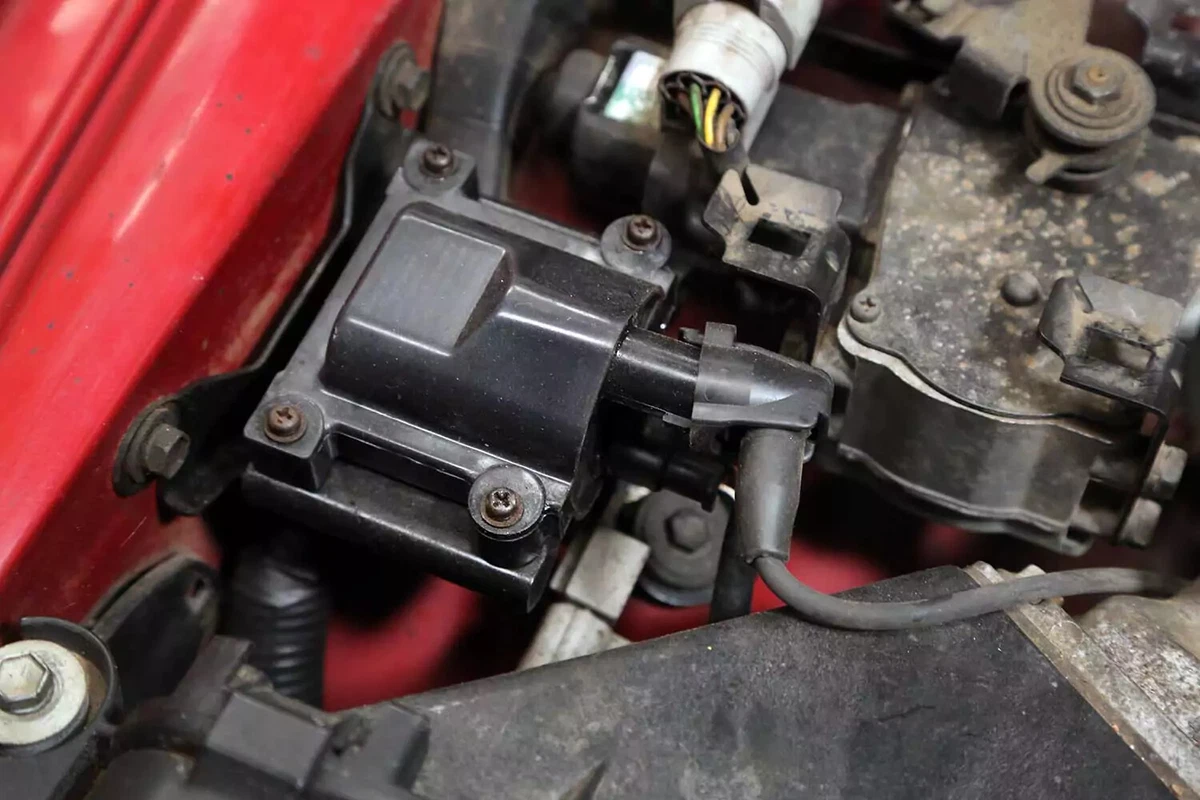

Our demo vehicle uses an inline six-cylinder engine with a single coil and distributor. Replacing the coil is very similar to vehicles without a distributor.

Trace the coil wire in the center of the distributor cap from the distributor to the coil. If you have multiple coils, the coils will be connected to the spark plugs with a separate plug wire for each plug.

On some vehicles, you might have to remove brackets or trim covers to access the coil. For our demo car, the coil is in the open. However, a trim panel that we removed partially covered the fasteners.

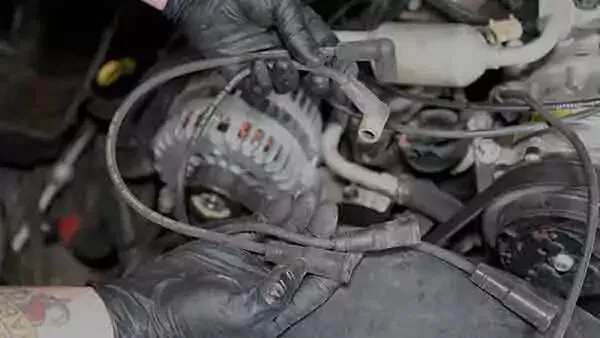

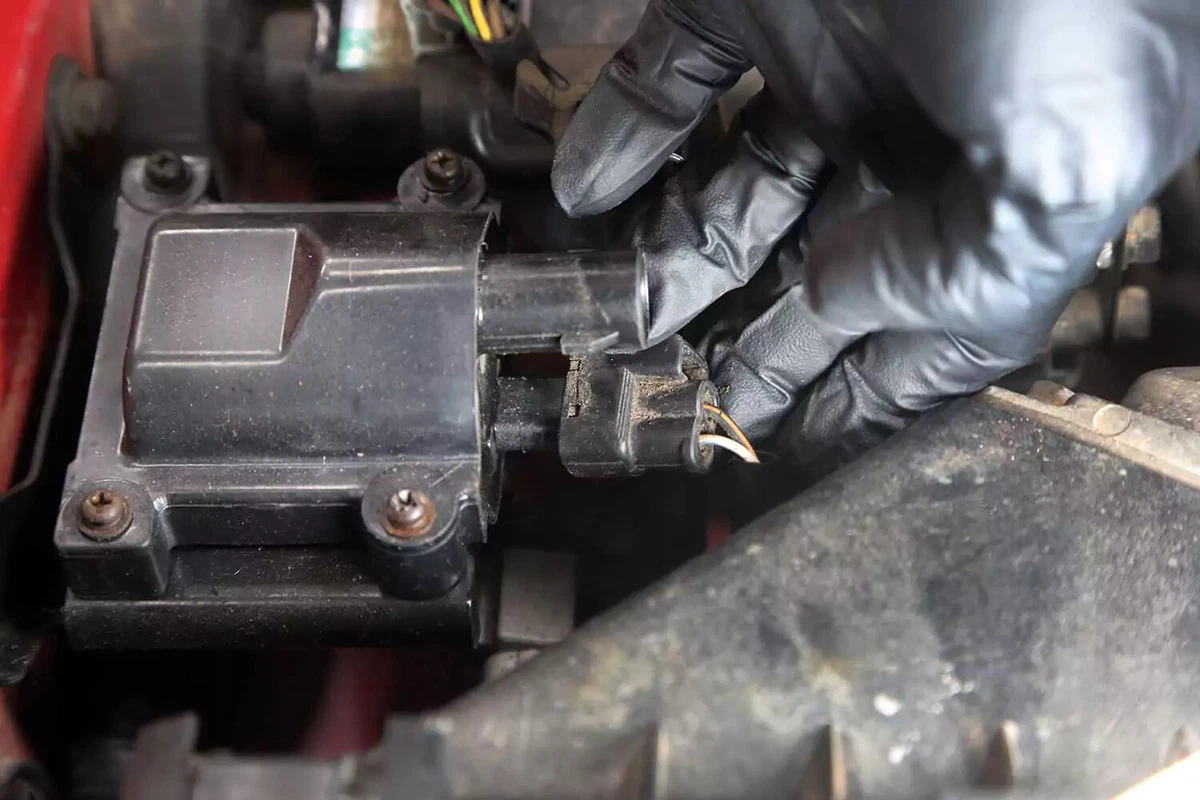

Remove the high-tension ignition lead from the coil. This car uses a hard plastic cover that snaps to hold the lead on the coil. But most vehicles use a basic silicone or rubber boot, and the metal terminal snaps into the coil.

Twist firmly and gently on the boot to break the seal. This will allow the wire to come out.

This is a great time to replace plug wires, cap, and rotor. The typical change interval for these parts is 30,000 miles or two years. Changing these now ensures your ignition system is in top working order.

Remove the power terminal from the ignition coil. Vehicles made in the 1980s or earlier use two threaded posts for power and ground connections. Newer coils use quick-release plastic plugs.

If your coil has a plug, unlock the terminal (if equipped with a locking tab). Then, press the release tab and disconnect the plug from the coil.

For threaded post coils, remove the nut and washers using a small socket (typically 3/8-inch for US domestic vehicles or 8 mm for cars using metric measurements).

Remove the ring terminal from each post. Use a piece of masking tape and a marker to note which wire goes to each post. This is an essential step. For reference, also take a photo with your phone. That will be a big help when it’s time to put everything back together.

Two to four screws or bolts secure the coils in newer vehicles. Meanwhile, vehicles made in the 1980s or earlier use a large band-clamp around a cylindrical coil. In that case, it uses four screws.

Remove the fasteners. Penetrating oil can help free rusty bolts or screws.

Remove the coil from the mounting bracket. If your vehicle has a cylinder coil, slide it from the band clamp.

Place the new coil into the bracket. Reinstall the fasteners. Use the original ones, or if fasteners were provided with the new coil, use those.

Snap the wiring harness plug into the new coil. Engage the locking tab if so equipped.

If your coil has threaded posts, install the ring terminals on the correct posts with a lock washer and nut. Tighten the nuts carefully. Don’t over-tighten.

High-voltage wires need protection from corrosion. The best way to protect your new coil and coil wire is by coating the wire and interior boot with dielectric grease or silicone paste. This seals the connection and provides a lubricant so the boot doesn’t stick to the coil housing.

Connect the coil wire from the distributor to the ignition coil. Most coil wires snap into place. A simple slip-fit metal terminal holds the wire in place. Push the wire into the coil until it bottoms out. On our vehicle, the coil uses a plastic cap outside the wire to lock to the housing.

The final step is to reinstall any trim or brackets you removed to gain access to the coil.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.